No products in the cart.

The brake and clutch cylinders are the crucial parts that convert the brake fluid into hydraulic pressure and enable the braking system to operate functionally.

Accessible and common as hydraulic cylinder part is, there is actually a huge difference behind the manufacture crafts, so the question is, how to make sure if you get the good quality ones when there are so many bargains on web?

1. OE Replacement v.s. Aftermarket Replacement

When it comes to parts replacement, it sure is OE replacement over aftermarket in terms of the warranty. However going with the OE replacement definitely costs more, and there are chances the part you seek is discontinued and no longer available.

In this case, aftermarket parts from a trust worthy brand is also a great and economic choice. Brake parts, a vital component for driving safety, definitely deserves more investment for precision and quality.

Just keep in mind to avoid the rebuilds or refurbished ones, after all it’s always better safe than sorry.

2. Material, Design & Manufacture Crafts

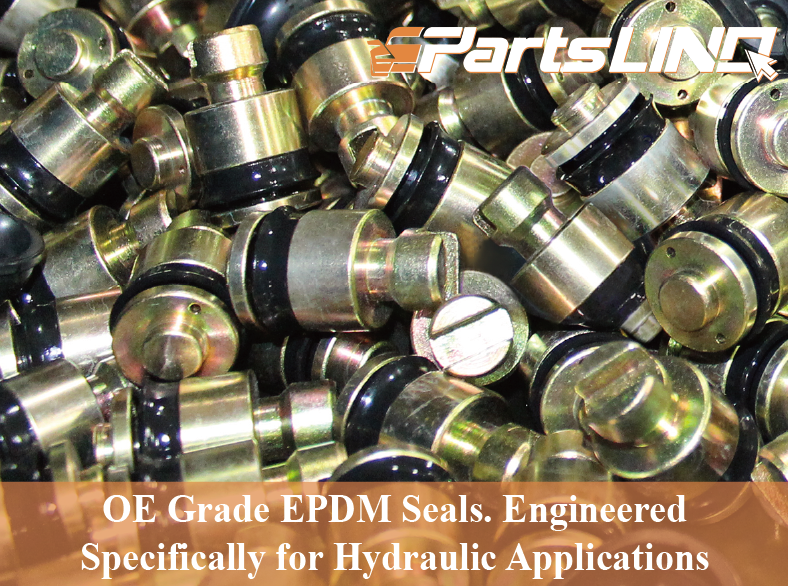

(1.) The Sealing : When the seal inside does not intact, it will result in the opposite pressure vacuum over the piston to disperse. Hence, the push-rod will start to malfunction because of equalizing pressure.

EPDM Sealing provide operating temperatures ranging from -60 to 150°C which acts as an excellent choice for extreme temperature application.

(2.) Special Surface Treatment : Heat treated and Electro- Coated components for extreme working conditions.

Heat Treated for stronger durability ; E-Coated for better protection under extreme working conditions

(3.) CNC Craftmanship : Micro-finished to reduce internal wear and improve durability.

Micro Finishing can be used to remove surface flaws and to provide additional strength and resistance.

3. Behind the Price – Extensive Product Testing as Safety Checkup

Lastly, what matters the most is the fitment and durability, and extensive independent testing is the direct way to ensure application and performance. That what behind what you pay for.